About Us

Company Profile

Since its establishment in 2000, our company has been dedicated to the research and production of LG and LD series cold pilger mills, covering thick-walled and precision tubes ranging from Φ3mm to Φ450mm. We also specialize in the design and manufacturing of straightening machines for pipes and rods. With an annual production of over 300 units, our products have transitioned from semi-automatic to fully automatic control, with rolling speeds upgraded from low to high velocity. We continuously pursue technological innovation, holding multiple patents and have been recognized as a high-tech enterprise. Our products are not only popular nationwide but are also exported to international markets including India, Korea, Russia, Pakistan, and Turkey.

Located in the picturesque eastern part of Zhangjiagang, our company benefits from excellent transportation links. We cover an area of more than 35,000 square meters, with a building area exceeding 20,000 square meters. Our facility is equipped with over 80 advanced machines, including an 80-ton gantry crane, 6-meter planers, T6113 boring machines, C6280 lathes, and C6163 extended screw rod lathes.

With over 200 employees, including more than 30 engineering and technical staff, we uphold the principle of "quality first, reputation foremost." Our commitment to providing premium products and professional services has earned the trust of both domestic and international clients. The company has been honored multiple times as a "Contract-Honoring and Trustworthy" enterprise by Suzhou City. We warmly welcome clients from around the world to visit and collaborate with us!

Assurance of quality :

We control the products’ quality strictly according to drawing and related standard .

The manufactured rollers and straighter are up to national standard , industrial standard or the technical condition written on the contracts which can meet customers’ requirements .

We can implement the system : Manufacturing under customers’ supervision and checking in the factory based on the contract .

After Sales Service :

During the products’ one -year warranty period ( wear parts and straighter are not included ) , we can provide the free maintenance for the products with quality problems .

The tenders are responsible for the equipment’s installing ,debugging and training the engineers , operators and maintainers about the products ‘ working principle , operation and maintenance .

Once the equipment break down after transaction , tenders must respond to the customers within one working day , if the problems can not be solved on line , tenders must go to site within 3 working days .

After the one-year warranty period , tenders still need to provide engineering service and maintenance to the problem equipment within the designing and manufacturing problems . They also should give them necessary technical support for the equipment’s normal function and operation .

History

The former Yiteng Machinery Co.,Ltd was founded by Hengli and partner.

2001

2002

Zhangjiagang Hengli was set up separately specialized in LD series small type cold pilger mill and other non-standard machinery such as Ball mill and food machinery

Hengli got nearly 20,000 ㎡ new land and the new-built factory was about 5000㎡ whose main production was pilger mill and straightener .

2005

2006

Hengli began to manufacture two-roller pilger mill and directed to large-type machinery .

According to customers’ advice and our own design ,the machinery was updated and rebuilt to improve the production effectiveness and quality which approved by the customers and realized annual sales volume to be 400 , getting more than 30,000 ㎡new land building 20,000 ㎡new factory for manufacturing pilger mill .

2011

2013

The rotated feed-in of pilger mill was controlled by photoelectricity .

Through the automatic and fine operation of private domain, create a sustainable private domain ecology for enterprises

2015

2014

Hengli started to manufacture feed-in without stopping developing to automatic way and started to design high speed pilger mill whose producing speed improved 60-70%

The LD , LG series pilger mill can process all kinds of tubes and pipes with the diameter from 5mm to 460mm . The outer diameter of straightener is from 8mm to 500mm . We will insist on exploring and creating to meet the clients requirements .

Nowadays

Our Factory

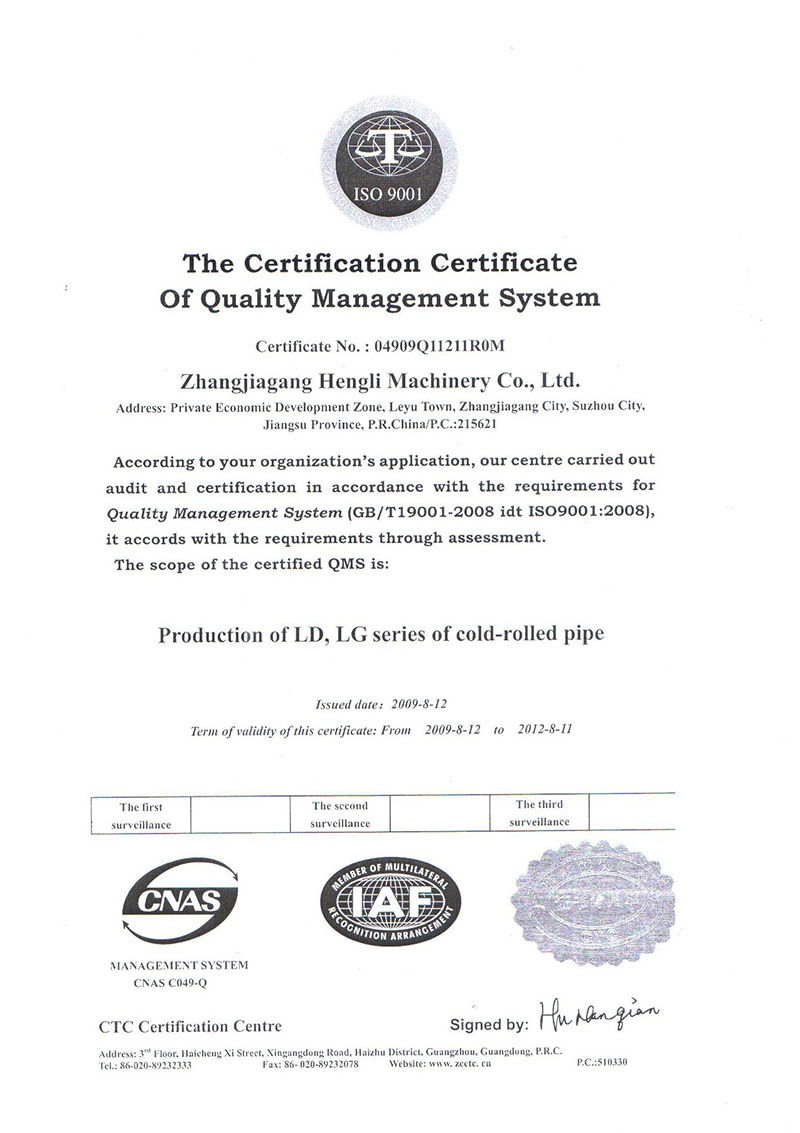

Certificate

_1.jpg)

_2.jpg)

_1.jpg)

_2.jpg)